coating thickness measurement units|coating thickness measurement methods pdf : wholesaler Ultrasonic paint thickness gauges can measure the thickness of coatings on nonmetallic substrates. The probe of the paint meter contains an ultrasonic transducer that sends a pulse through the coating. web20 de fev. de 2023 · Eublack abre sistema para cadastramento e formação de equipes na nova empresa após encerramento da operações da Jeunesse no Brasil. Mas qual a diferença entre um .

{plog:ftitle_list}

Resultado da The latest tweets from @gremio

Ultrasonic paint thickness gauges can measure the thickness of coatings on nonmetallic substrates. The probe of the paint meter contains an ultrasonic transducer that sends a pulse through the coating.The Elcometer range of digital coating thickness gauges has been specifically designed to provide highly accurate, reliable and repeatable coating thickness measurements on almost . Typical coating thicknesses can range from a few nanometres to several centimetres. As an example, Titanium Zirconium (TiZr) coatings can be 1nm to 5nm thick, . Step 4: Measurement of Coating Thickness. Step 5: Correction for Base Metal Reading (if acquired). Each of these five steps will be described in this article. Some History. SSPC-PA 2, was originally published as a .

Elcometer 500 Model T Coating Thickness Gauge, C1 & C2 coating thickness probes, C1 & C2 probe measurement foils: 1, 2, 3 & 8mm (40, 80, 120 & 310mils), Elcometer 456 Model B Ferrous Integral Gauge, Elcometer 456 .

Benchtop units manufactured by our company provide one measuring solution for all measuring applications including coating thickness measurement and material testing. Our benchtop units have unique design that can be adapted .

Measure the thickness of painted metal without removing the coating. The ultrasonic probe provides highly accurate readings. This gauge comes with a calibration certificate traceable to NIST that states it has passed a test for accuracy. It also includes a USB cord for connecting to your PC. Use the included ultrasonic gel for maximum surface contact. .

It is provided with graphical display for having a clear view of measurement. It has various predefined measurement applications for various types of metal coatings. Our benchtop coating thickness measurement unit – couloscope CMS2 has selectable measurement units and has various display languages options such as Asian, South American and .Table 2 indicates that the galvanizing thickness of Coating Grade 100 is 100 microns or 3.9 mils. The weight of the galvanizing is 705 grams/square meter or 2.3 ounces/square foot. Methods for Measuring Galvanizing Weight or Thickness. Coating weight or thickness can be measured by one of four methods.

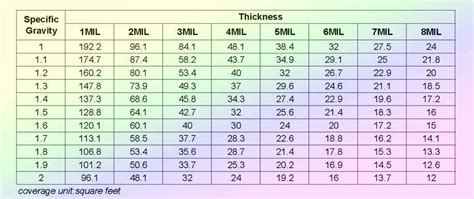

Powder coating thickness measurements can be taken before and after curing. Substrate type, powder coating thickness range, part shape, and economics determine the best method to be employed. . Units of Measurement Mil. The normal standard used in powder thickness measurement is the mil, where 1 mil is equal to a thousandth of an inch (1/1000 . The issues that determine what method is best for a given coating measurement include the type of coating, the substrate material, the thickness range of the coating, the size and shape of the part and the cost of the equipment. Commonly used measuring techniques for cured organic films include nondestructive dry film methods such as magnetic, eddy current, .

Coating thickness measurement is the determination of the layer depth of a coating or film on a particular substrate. Coating thickness can be measured when the film is wet or dry. . The sensor of a coating thickness measuring device either can be found inside the unit or within a separate probe. A coating thickness gauge with a built-in or .

2 Technical Advice Measuring Dry Film Thickness (DFT) of Powder Coatings Measuring Dry Film Thickness . The units of measure are predominantly micro-meters (μm). This is very small: 1μm – 1/1000 of a mm. A common range of DFT is 50 – 100μm for powder coatings.The specification ASTM E376 contains information for measuring coating thickness with magnetic and electromagnetic gauges as accurately as possible by explaining how and where to take measurements as well as guidelines for reducing errors. A few key requirements include: Readings should not be taken near an edge, hole, or inside; Measurements on large products .3. Place a measured shim (comes with the gage) onto the prepared, uncoated metal surface to be coated; Adjust the gage reading to match the thickness of the shim. 4. Measure the coating thickness. 5. There should be no “correction” for the gage, as any effect of the base metal has been eliminated. Bill Corbett, KTA

Figure 10: Schematic diagram of the influence of substrate conductivity on coating thickness measurements. Certain probes, such as the FTA3.3 probe [Helmut Fischer GmbH], is able to compensate for some differences in electrical conductivity, for example brass (58MS/m), aluminium (45MS/m) and copper (58.6 MS/m) it still has difficulties changing .The ability to gauge thickness measurement without requiring access to both sides of the test piece, offers this technology a multitude of possible applications. Paint thickness gauges, ultrasonic coating thickness gauges, digital thickness gauges and many more options are available to test plastics, glass, ceramics, metal and other materials. .If the coating thickness is outside the measurement range, the Elcometer 500 tells you on the display. Intelligent The Elcometer 500 measurement probes are supplied with user replaceable probe tips. If the tip is damaged or wears during use you can replace it and carry . Measurement units; μm, mm, mils, inch .

When undertaking a project with a high performance coating, you need to think about how you will measure the coating thickness to ensure it is applied to specification. By monitoring and recording your coating thickness .Coating Functions; Thickness Conversion; Hardness Conversion; Automotive Apps; General Engg Apps; Power Sector Apps; Pump and Valve Apps; Steel Plant Apps; Thickness Conversion Unit conversion table for coating thickness. Micrometers (um) Millimeters (mm) Inches: Mils (Thousandths) "Tenths"Dry film thickness (DFT) plays a significant role in meeting the quality and performance of coatings in various industries. Whether it is a paint finish on an automobile, protective coating on a bridge, or a coating on a metal substrate, the thickness of the dry film is a critical factor. Not only does it affect the lifespan and durability of the coating, but it also determines its ability to . Accurate coating thickness measurement enables plating, anodizing, powder coating, and other coatings, preventing corrosion or wear of metal substrates. . Easier, more accurate aerospace coating and plating measurement with handheld units will help improve quality checks so defects can be immediately detected and corrective action taken to .

The PosiTector 200 C Ultrasonic Coating Thickness Gage (Standard or Advanced) is ideal for measuring most paint and coatings on concrete applications.With a paint thickness measurement range of 50 to 3,800 µm (2 to 150 mils), this thickness gage is recommended for customers desiring a single non-destructive measurement solution for most applications.Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in coating thickness measurement. Whether single or multilayer coatings, painted or galvanized, magnetizable or conductive. While standard paint and powder coating thickness measurement requirements can be accomplished using the magnetic induction or eddy current methods, some situations require a different technique. . metal coatings, such as copper, aluminum or brass over a nonferrous or electrically nonconductive substrate. The unit shown in Figure 7 uses the .Measure the total thickness of a coating system or up to 3 individual layer thicknesses in a multi-layer system. Graphics mode with screen capture for detailed analysis of the coating system; Storage of 250,000 readings in up to 1,000 batches;

Option #2—PosiTector 6000 The PosiTector 6000 provides similar measurement capabilities with higher accuracy and resolution. Rugged, versatile gage for total coating thickness measurement on metal panels. Optional features include interchangeable probes, on-screen statistics, printer output, and downloading readings to a computer.State-of-the-Art Coating Thickness Measurement 2 Coating Thickness Measurement Instruments FMP10, FMP20, FMP30 and FMP40 The Fischer proven portable instruments with exchange- able probes allows for non-destructive and highly pre-cise measurements of coatings. Whether for quality control in a manufacturing process or incoming inspec-

An example of FIB cross-sectioning workflow: (a) the sample is inserted in the chamber with 0° tilt; (b) a thin layer of metal is deposited on the surface using the electron beam; (c) the stage .

Coating thickness measurement on production line is a process to determine the thickness of a coating applied to a substrate. It is done to ensure that the coating is consistent, uniform and within specified thickness limits. The most common methods for coating thickness measurement are: – Non-destructive techniques: Magnetic induction; Eddy .

ut wall thickness measurement

WEB16 de jan. de 2024 · Na partida de ida entre Wolverhampton e Brentford tiveram 11 escanteios. Aliado a isso, a média de cantos nos últimos jogos do Wolves como mandante é de 8,2, enquanto do Brentford fora de casa chega a 8,3. Dessa forma, apostaremos que haverá 10 ou mais escanteios neste duelo decisivo. Palpite Wolverhampton x Brentford: .

coating thickness measurement units|coating thickness measurement methods pdf